Features

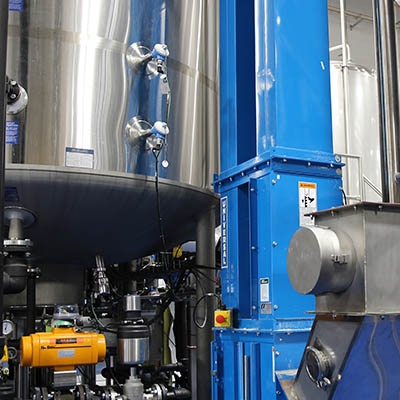

- 100% 304 stainless steel construction, including all non-product contact and structural steel

- 2B product contact material finish, with internal welds polished #4

- Designed with adequate free board above the maximum working volume

- Glass cover manway

- Low chloride ceramic blanket insulation

- Fully welded 304 stainless steel outer sheathing

- Rotary sprayballs to clean vessel

- Mueller grist hydrator designed to properly mix grist and tempered water at a customer specified mash in rate

- Integrated steam jackets for temperature adjustment during step mashing

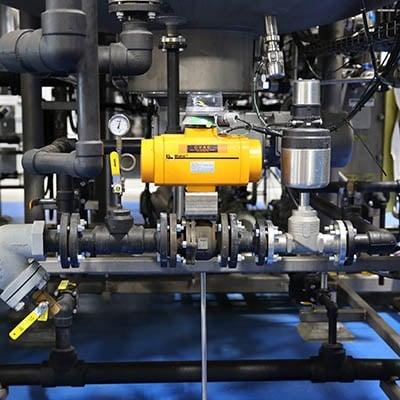

- Low shear mixer designed to create homogeneous temperature and moisture content while mitigating shear damage to the malt husks

- Properly sized outlet to eliminate shear damage and clogging when pumping mash to the lauter tun

Specifications and Sizing

Work with our innovative engineers to create a mixer that is perfect for you and your facility. At Paul Mueller Company we work to meet all your needs and with our various shapes, sizes, and specifications we are confident that we will be able to make a high quality product that you will love.