Calculer les besoins

Le bon matériel de transfert de chaleur permet un déroulement plus rapide des opérations, des procédés plus durables, et des économies qui viennent s’ajouter à votre bénéfice net; mais vous devez savoir calculer correctement vos besoins. Voilà comment nous pouvons vous aider.

Pour tout liquide, peu importe le volume

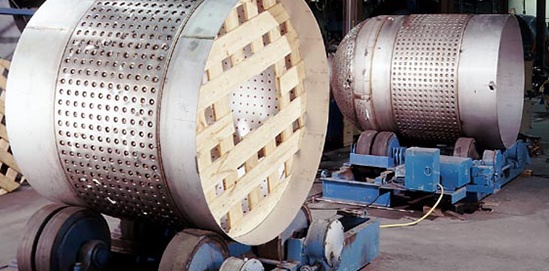

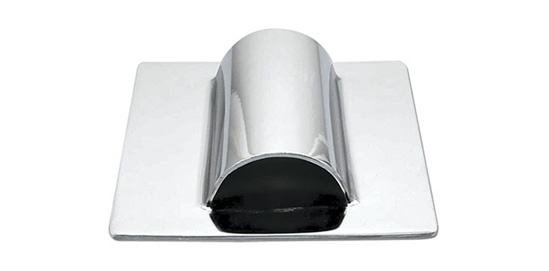

Notre surface de transfert de chaleur extrêmement polyvalente peut faire varier la température de tout type de liquide dont vous ayez besoin, peu importe le volume. Rapidement. Nous pouvons concevoir, développer et fabriquer le bon type de matériel pour votre procédé : sections à pinces, feuilles à double paroi, cônes, chutes, ensembles étagés et panneaux pour immersion.

Plus de 75 années d’expérience en procédés

Chez Paul Mueller Company, nous sommes fiers de mettre nos 75 années d’expérience en procédés au service de nos clients. Nous utilisons des pièces de qualité et un savoir-faire professionnel afin de créer une solution de transfert de chaleur sur mesure qui maximisera le rendement de votre entreprise et vous permettra de réaliser des économies tout au long de la durée de vie de votre matériel.